#Whitepaper

PORT TERMINAL PLANNING – PLANNING OF PROCESSES UTILIZING AB OVO’S SOLUTIONS

1. The Challenge

The current market situation of diminishing margins and tightening delivery windows has led to increased complexity in planning & scheduling processes. Therefore, the efficient use of resources is top priority. An Advanced Planning & Scheduling solution has a huge cost savings potential for planning departments, while also increasing delivery reliability and flexibility. Ultimately, this leads to a healthier bottom line and increases competitive advantage. Port Terminal activities are integral parts of the supply chain in terms of service level agreements. Living up to quality and performance levels is a daily challenge, both in terms of economics and in terms of planning.

Performance is measured in terms of minimizing turnaround times and vessel delays. This is tough to manage since the various services involved in the loading/unloading of vessels are interdependent; unmooring can only be started when all other services are finished, vessels can’t share the same parts of a berth and different products can’t share the same transportation pipeline.

Port Terminal Planning

Port Terminal activities are integral parts of the supply chain in terms of service level agreements. Living up to quality and performance levels is a daily challenge, both in terms of economics and in terms of planning.2. The Ab Ovo Port Terminal Solution

Planning and (detailed) scheduling of port terminal processes is characterized by complex business logic and numerous constraints. A planning department has to take a variety of interdependencies into account, such as the alignment of demand planning, product contamination (for liquid bulk), last-minute orders, shortened load/unload times, various handling rules (e.g. sequence dependent setup times), inventory management at the storage yard, alignment setup times), inventory management at the storage yard, alignment with transport planning, production disturbances (e.g. equipment breakdown), equipment maintenance, workforce planning and container planning.

Ab Ovo’s expertise is modeling this complex business logic, including all constraints, using specialized Advanced Planning & Scheduling (APS) software. Ab Ovo developed and implemented several planning applications for different port terminal types: Dry Bulk Terminal, Liquid Bulk Terminal, RoRo & Container Terminals.

These applications (or combinations of them) cover roughly 80% of all port terminal processes. The remaining 20% are often unique and company-specific.

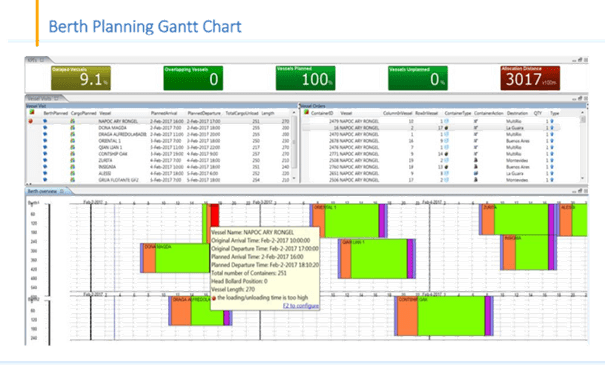

3. Berth Planning

In general, berthing places are quite flexible and are able to process a number of vessels simultaneously as long as the total length of all moored vessels does not exceed the length of the berth (plus some necessary margins). However, in some terminal systems, berthing positions can be restricted by the equipment used for loading/unloading, e.g. cranes, or pipeline connections.

Ab Ovo has handled two different variants of berthing process: with several vessels per berth and with one vessel per berth for various planning periods. Other variants of berthing processes can (in most cases) be easily modeled as a combination of those two. One of the most important functionalities of a planning module for berthing processes is visualization of the berth usage. In our solutions, we use Gantt charts (see below) which aid visualization by indicating which part of berth is occupied at what specific time (the vertical axis indicates berth positions, and the horizontal axis represents time).

Any berthing process includes different operations, such as (in addition to loading/unloading):

- mooring/unmooring

- lowering of ramps

- connection of pipelines

All of these standard berthing processes and their durations can be easily predefined by users for each type of vessel or each type of loading/unloading situation, and the system will automatically add necessary durations to the planning as soon as the vessel is planned to a berth. All other durations that depend on the planning decisions in other modules (e.g., equipment and workforce planning) are immediately updated as soon as there are changes in those planning decisions – this is called “propagation,” a key feature of our solutions. This way, planners are immediately informed about unnecessary disturbances in the berth planning process and can take appropriate remediation actions.

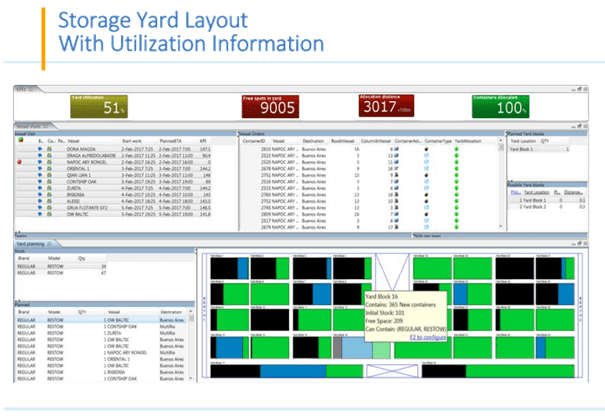

Storage Yard

Many factors affect the planning of storage yards – text views can be created and used so the end user can drill down to necessary information4. Storage Planning

Storage yards are another important part of any port terminal. Improper planning of the storage yard can negatively influence the work of the whole terminal. Vessels cannot be loaded if there is no cargo at storage, nor can they be unloaded if there is no space available for cargo. Planners need to minimize the transportation costs from vessel to yard blocks. In storage yard planning, the proper representation of data plays an important role. For example, having representation based on the storage yard layout and its utilization for RoRo or Container Terminals, the planner can easily determine where the best places are for storing and what berth is best berth for the vessel.

Loading/Unloading

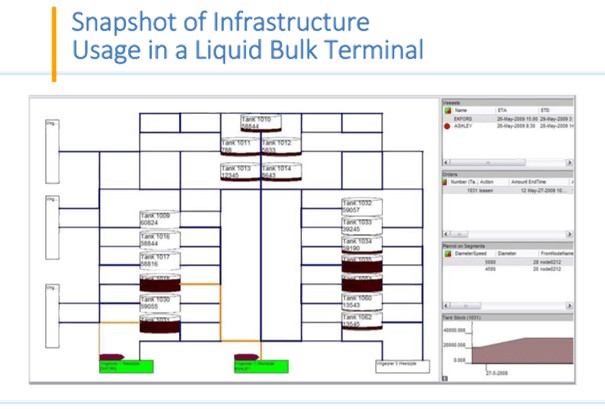

Terminal equipment planning is challenging due to the vast amount of combinations of stationary and mobile equipment required for each job5. Planning of Loading/Unloading Equipment

For the transportation of cargo between vessels and other parts of the terminal (e.g., storage yard, train/truck loading), different types of terminal loading/unloading equipment must be used. Those types include pipelines for liquid bulk, stacking/reclaiming machines and conveyers for dry bulk, container stackers (e.g., fork lifts, straddle carriers) and transporters (including automated guided vehicles – “AGVs”) for container terminals, etc.

Terminal equipment planning is challenging due to the vast amount of combinations of stationary and mobile equipment required for each job. There are also a vast number of planning constraints, including but not limited to labor laws, carrying weight maximums, etc. One example is the pumping of liquid bulk, which requires several pieces of equipment. For each piece of equipment, no product contamination can occur, so each piece of equipment can only be used for specific combinations of products, or it has to be properly cleaned between uses.

Another example is the use of container cranes. Cranes are often placed on rails, and planning must be done in such a way that they do not hinder work for other vessels. As in the modules described above, different data representations are necessary here in order to make planning of the terminal equipment easier.

In our solutions, we use Gantt Charts. In this case, the Gantt Chart contains more information about current and future planning, and the infrastructure snapshots, on the other hand, help guide the use of different combinations of equipment.

Furthermore, our applications contain a number of different constraints, business rules and usage KPIs, which guide planners as they make the best planning decisions.

Workforce Planning

Proper planning of a workforce is still very important, and it can be quite complex due to the substantial number of different rules and constraints imposed by employee skills & labor regulations,6. Workforce Planning

Workforce planning is less restrictive to changes and reconfigurations in comparison to the other processes. Capacity shortages can be compensated for with the use of external employees. However, the proper planning of a workforce is still very important, and it can be quite complex due to the substantial number of different rules and constraints imposed by employee skills, labor regulations, etc. As before, the proper representation of data and planning results is necessary.

Ab Ovo utilizes capacity charts and list forms to provide planners with necessary information.

Key Benefits

Cost savings | Increasing delivery reliability | Healthier bottom line | Growth of competitive advantage7. Planning of Other Facilities

Port terminals can also include other facilities, such as rail road terminals, truck terminals, cargo pre-/post-processing facilities, custom offices, etc. The flexibility of our planning solutions allows us to integrate this easily and to provide a 100%-fit solution for each customer. Integral planning of all terminal activities and flexible real-time performance overviews of each planning decision are the most important asset of our planning solutions.

Relevant KPI’s are visible for each individual planner in order to support making the best possible planning decisions. In this way, the planning process becomes transparent for all users of the entire system (e.g., operators, planners, managers etc.) and each user can see how their individual decisions may influence performance of the whole system. Furthermore, the planning system allows planners to create individual (offline) planning environments with the possibility for extensive What-If analysis and simulations, without interfering with other planners and their planning decisions.

Finally, our planning solutions contain a number of built-in methods for optimal decision making, based on external state-of-the-art optimization modules and on our own (system-specific) algorithms. In this way, planners can always be secure in their decisions.

Key Benefits

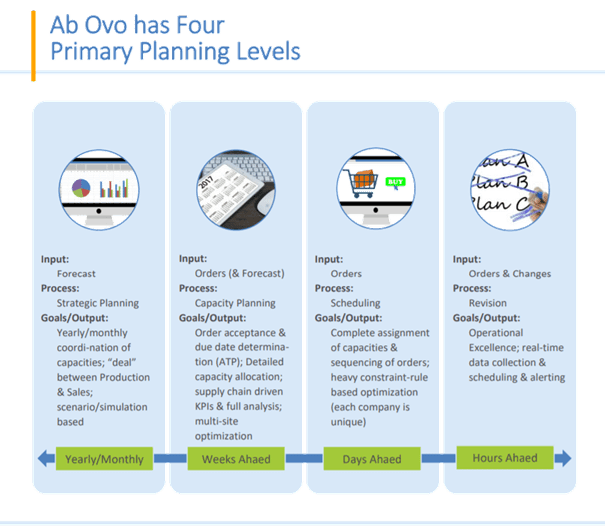

Cost savings | Increasing delivery reliability | Healthier bottom line | Growth of competitive advantage8. Our Planning Vision

Ab Ovo offers planning solutions which cover the entire planning process, from strategic and long-term planning to operational planning. Especially in large and complex logistic-oriented environments, organizations gain a competitive edge by optimizing their long- and mid-term planning processes.

Strategic Planning

The strategic planning is an activity which is mainly controlled by the input of the board of directors (strategic plans and budgets).

Strategic issues, such as expected demand, future growth or consolidation, are translated into activities that are needed to

realize these strategic goals. Think of the amount of resources like manpower or physical resources (e.g. cranes, pipelines, storage capacity, handling equipment, etc.) which are required to realize the strategic goals. These activities result in a long- term (strategic) plan which comprises a period of six months to two years.

Capacity Planning

The capacity planning comprises the shortterm availability of resources. Think of the service agreements with customers,

seasonality in demand for delivered goods, holiday planning, etc. The time scope is approximately a week to several months. The capacity plan is largely based on (rolling) forecasts.

Scheduling

The actual assignment of resources to jobs is an activity which is performed up to a few days/weeks before the actual planned date. In this planning activity, all constraints are involved and an optimal schedule is generated. The generated schedule is primarily based on actual vessel arrivals and physical resources. In the scheduling

phase, mathematical optimization generates (optimal)schedules.

Day of Operation

A schedule is a plan and disturbances will influence this plan. These disturbances have to be dealt with while maintaining the

best possible overall planning. Revision is often real-time, handling all sorts of disturbances (among others: equipment breakdown, last-minute orders). Changing the planning for optimization reasons is

often not appropriate at this stage.

Key Benefits

Cost savings | Increasing delivery reliability | Healthier bottom line | Growth of competitive advantage9. Benefits

This yields to following Business Benefits:

ROI: The solution’s benefits bolster a short time to ROI.

Reduce costs (penalties): More information concerning the planning process will improve it. The improvements can be measured by means of parameters (KPIs). These KPIs can be expressed in various ways; in terms of costs (penalties because of delayed vessels) is obvious, but also other types of value are possible: efficiency, SLA, goodwill, etc.

Planning optimization: Better insight into planning and its interdependencies.

Quality improvement: Better insight in the actual process leads to a better and more feasible planning situation with less (last-minute) disturbances.

#BetterTogether

DELMIA Quintiq Platinum Partner

DELMIA Quintiq (part of Dassault Systèmes) is a leader in delivering state-of-the-art supply chain planning and optimization solutions that help customers reduce costs, increase efficiency and improve bottom-line results. DELMIA Quintiq and Ab Ovo have an extensive shared history. We are both innovative leaders in rail, aviation, maritime, manufacturing, retail, and logistics. Ab Ovo is one of DELMIA Quintiq’s longest-standing and most experienced partners. For more information, visit DELMIA Quintiq.